Applications of SILZ-VR51 Polysilazane High-Voltage Insulation

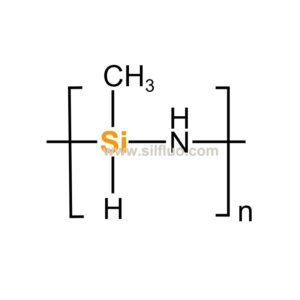

The exceptionally high bond energy and stability of Si–N bonds in polysilazane result in stable molecular orientation under electric fields, effectively suppressing electron migration. Combined with highly insulating and heat-resistant composite fillers, SILZ-VR51 delivers a high-voltage-resistant insulation coating with outstanding comprehensive performance.

1. Molecular structure optimization technology – ultra-high dielectric performance

Through theoretical design and extensive experimental validation, SILZ-VR51 adopts an optimized “tassel-like” branched structure. During curing, this structure forms a dense and uniform three-dimensional crosslinked network. Together with the strong Si–N bonds, the coating achieves excellent mechanical strength and long-term stable electrical insulation performance, with minimal degradation due to aging, wear, or corrosion.

2. Composite filler spatial integration technology – higher density, stability, and integrity

Multiple grades of high-insulation, high-temperature-resistant fillers with different particle sizes and morphologies are strategically combined to form a robust skeletal structure. Special stabilizing additives further enhance resin–filler interfacial bonding, minimizing interfacial defects. Additives containing large π-bond systems can capture localized micro-currents, significantly improving overall performance, including heat resistance, wear resistance, corrosion resistance, aging resistance, strong oxidant resistance, and extended service life.

Technical Specifications

| Test Item | Specification | Test Method |

| Appearance / Color | Black / White / Gray / Olive green / Yellow (customizable) | Visual inspection |

| Density | 1.75–1.90 g/mL | GB/T 6750-2007 |

| Solid Content (120 ± 2 °C) | > 45% | GB/T 1725-2007 |

| Pencil Hardness | ≥ 5H | GB/T 6739-2006 |

| Adhesion | Grade 0 | GB/T 9286-1998 |

| Neutral Salt Spray Resistance | 30 d, no blistering, cracking, or rust | GB/T 10125-1997 |

| Artificial Aging Resistance | 30 d, no corrosion, chalking, cracking; slight color change | GB/T 1865-2009 |

| Dielectric Strength | ≥ 105 V/mm | ASTM D149 |

| Electrical Resistivity | ≥ 10¹³ Ω·m | GB/T 35856-2018 |

| Temperature | <10°C | 25°C | 180°C | 200°C | |

| Curing Conditions (DFT 12–100 μm, RH 70%) | Surface dry time | 2h | 2h | 0.1h | 0.1h |

| Full Cure Time | >6d | >5d | 0.5h | 0.5h | |

Special Note: This product is a two-component thermosetting product. Mixed coatings should be used within 4 hours. During extended application periods, ensure application tools are thoroughly cleaned to prevent adhesion. The recommended interval between repeated sprayings is 5-8 minutes, with each coat less than 40µm in thickness.

Standard Processing Procedure: Surface Cleaning → Roughening → Cleaning and Blowing → SILZ-VR51 Treatment → Curing

Instruction Manual

- Roughening: Before coating, grind or sandblast the substrate surface to remove rust, dust, dirt, etc. Roughening significantly affects the coating effect; optimal Sa2.5, minimum St3 (no oxide scale) (GB/T 30790.4-2014), so please pay close attention.

- Cleaning: Use a special cleaning agent or degreaser to remove residual oil, dust, etc., from the roughened surface.

- Substrate Drying: Ensure the substrate surface is dry and clean before coating.

- Coating Mixing: This product is a two-component product. Take an appropriate amount of coating according to the mixing ratio and mix thoroughly. Filter through a 180-mesh filter for later use.

- Coating Application: For laboratory spraying, a 1.0-1.5 mm nozzle spray gun will provide better appearance and uniformity. 6. Curing: For coating thicknesses exceeding 100µm, room temperature curing is recommended. For coating thicknesses below 100µm, either room temperature or high-temperature curing is possible. For film thicknesses of 50-100µm, curing at 180℃ for 40 minutes is recommended. For film thicknesses below 50µm, curing at 180-200℃ for 30 minutes is recommended.

Storage & Transportation

- Store in accordance with applicable regulations. The storage environment should be dry, cool, and well-ventilated, away from heat and ignition sources. Containers must be tightly sealed and handled with care.

2. Recommended storage temperature: 10–30 °C. Shelf life: 6 months.

3. Reseal containers tightly after opening if not fully used.

4. Prepared but unused coating materials must not be recycled and should be disposed of in accordance with local regulations.

5. Products beyond shelf life may only be used after passing quality inspection.

Packaging

In 1kg, 2kg, 5kg, 25kg pail.