1. Introduction: The “Crown Jewel” of Organosilicon Chemistry

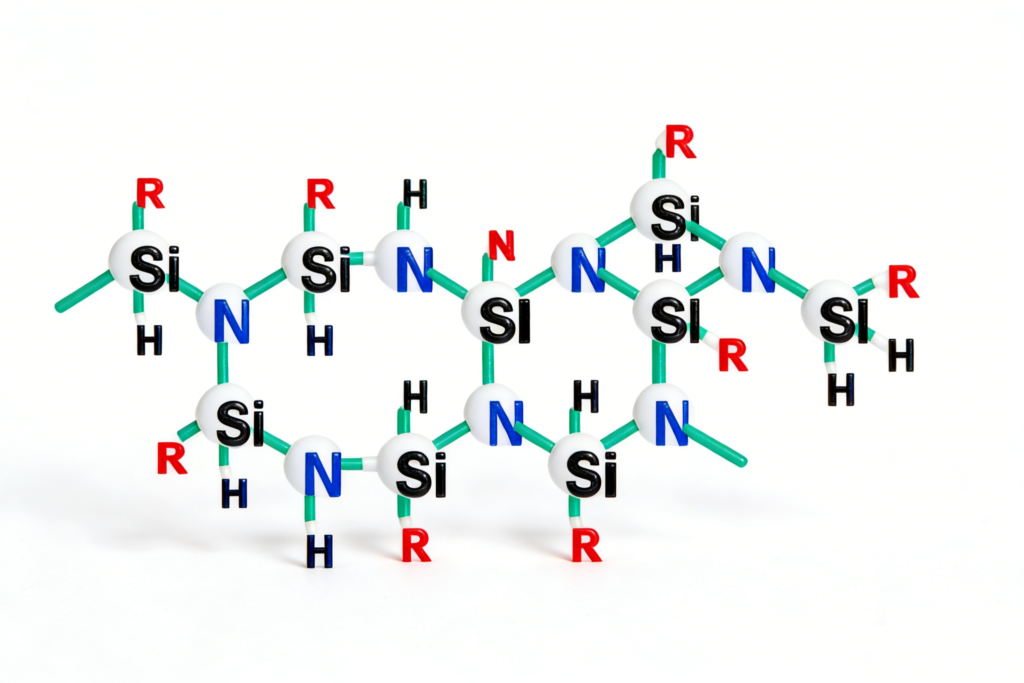

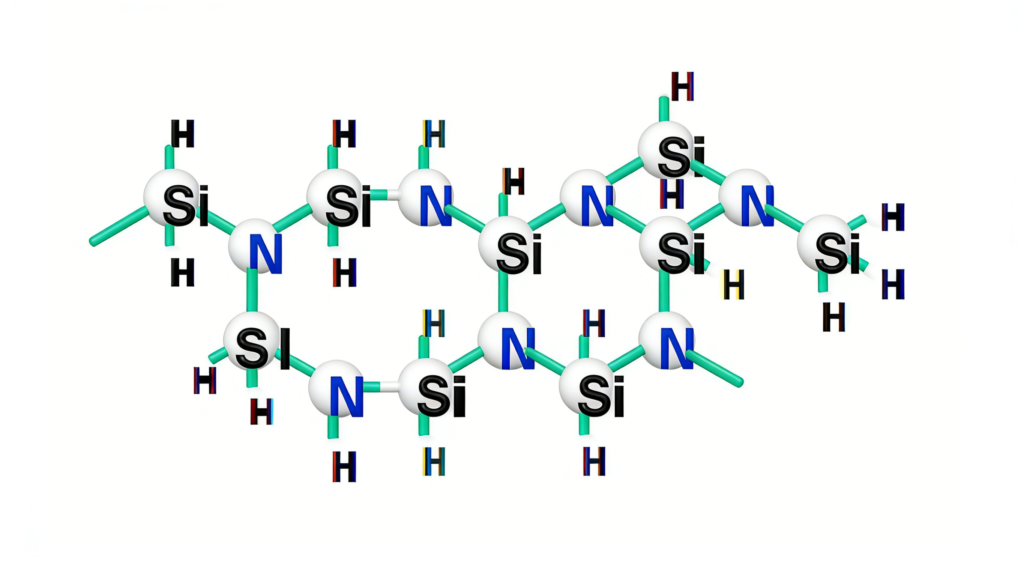

While the world is familiar with silicones (polysiloxanes) containing Si-O bonds, a unique and powerful class of materials has emerged: Polysilazanes (PSZ). Characterized by a Si-N (Silicon-Nitrogen) backbone, these polymers are notoriously reactive and difficult to synthesize, yet they offer performance properties unmatched by traditional silicones.

A Century of Evolution

- 1921:First discovery via the ammonolysis of chlorosilanes.

- 1990s: Riedel’s research group successfully introduced Boron to create Si-B-C-N ceramics, shifting focus to modified polysilazanes.

- Today:The industry has moved from basic synthesis to advanced applications, including Organic Polysilazane Resins (OPSZ), Perhydropolysilazane (PHPS), and Polymer Derived Ceramics (PDCs) like SiCN and SiC materials.

![]()

2. Properties: Why Engineers Choose Polysilazane

Polysilazane serves as a bridge between organic polymers and inorganic ceramics. It functions as a Ceramic Precursor, capable of transforming into silica, SiCN, or SiCNO ceramics under high temperatures.

Key Performance Metrics:

- Extreme Hardness:Cured coatings achieve a pencil hardness of 8H+.

- Thermal Stability:Converts to ceramic phases (SiCNO/SiCN) at high temperatures.

- Versatility:Excellent adhesion to various substrates, radiation resistance, and hydrophobicity.

Applications:

- Aerospace:High-temp composites.

- Semiconductors:Dielectric layers.

- Industrial:Anti-corrosion and anti-graffiti coatings.

3. Market Landscape & The Supply Chain Challenge

Despite its superior properties, Polysilazane adoption has been slowed by complex synthesis processes and instability during transport. The market has historically been an oligopoly dominated by Western giants:

Organic Polysilazane (OPSZ): KiON (USA), Dow (USA), Merck (Germany).

Perhydropolysilazane (PHPS): Clariant (Switzerland), AZ Electronic Materials (UK), Teon (Japan).

Silfluo Solution: Silfluo has broken through these technical barriers, establishing robust mass-production capabilities for both low and high-molecular-weight polysilazane resins. By localizing production and optimizing synthesis, Silfluo aims to reduce application costs by over 50%, democratizing access to this advanced material.

| Basic Coating Data | ||

| ltem | Index | Test/Standard |

| Coating Appearance | Black/White/Gray/ Military Green/Yellow |

Visual |

| Coating Component | Two-Component | |

| Mixing Density | 1.75~1.90g/cm³ | Measured |

4. Product Spotlight: SILZ-VR51 High-Voltage Insulating Coating

Silfluo and its R&D team have recently unveiled the SILZ-VR51, a revolutionary “Ambient Cure, High-Temperature, Insulating & Anti-Corrosion Coating.”

Technical Specifications

Binder System: Modified Polysilazane Resin.

Curing Mechanism: Dual-Cure (Ambient temperature or High-temperature cure capability).

Composite Fillers: Alumina (Al2O3), Sericite (Mica), and Fumed Silica.

Dielectric Strength: ≥105 V/mm (100 kV/mm).

Thermal Endurance: Long-term service at 400°C – 500°C without cracking, peeling, or discoloration.

| Project | Index |

| Temperature Resistance | 400-500℃ |

| Appearance | Dense, saturated, smooth |

| Dielectric Strength | ≥10⁵V/mm |

| Electrical Resistivity Hardness | >10¹³Qm |

| Hardness | >5H,GB-T6739-2006 |

| Anti-corrosion | 5%NaC130d non-rust |

| 5%HSO.30d non-rust | |

| 5%ENO,30d non-rust | |

| Adhesion | 0 Grade, Cross-shaped pressure-sensitive adhesive tape method; GB/T 1821-89(89) |

| Weather Resistance | 2000h, Pass. The coating remains unchanged,GB/T1771-91 |

| Salt spray Resistance | 30d No bubbles, no cracks, no rust |

| Drying Time | Surface drying time: 2 – 4 hours; Full drying time: ≥ 48 hours |

| Thickness | 12um-150um |

Performance Mechanism

“Tassel-Type” Branching: Through 100+ experiments, the resin structure was optimized into a hyperbranched “tassel” form. This ensures a dense, 3D cross-linked network upon curing.

Interface Engineering: The high bond energy of the Si-N backbone stabilizes molecular alignment in electric fields, preventing electron migration.

Defect Elimination: Special stabilizers containing large π-bonds are used to enhance the resin-filler interface, capturing weak local currents and eliminating insulation defects.

Applications

This coating functions as a superior Conformal Coating, suitable for:

- Substrates:Aluminum, Carbon Steel, Stainless Steel, Cast Iron, Titanium Alloys.

- Sectors:Power electronics packaging, Photovoltaic facilities, Electric heating equipment, and Stone sealing (anti-mold/moisture).

5. Future Outlook (2022-2026)

Driven by the demand for Ceramic Matrix Composites (CMCs) and industrial protective coatings, the global Polysilazane market is projected to grow at a CAGR of >16.5%.

Silfluo continues to lead the charge in domesticating this technology, offering a complete portfolio from Chlorosilanes to Amorphous Ceramics (Si-C-N). By solving the cost and supply chain issues, Silfluo is polishing the “Crown Jewel” of the silicon industry for widespread industrial use.