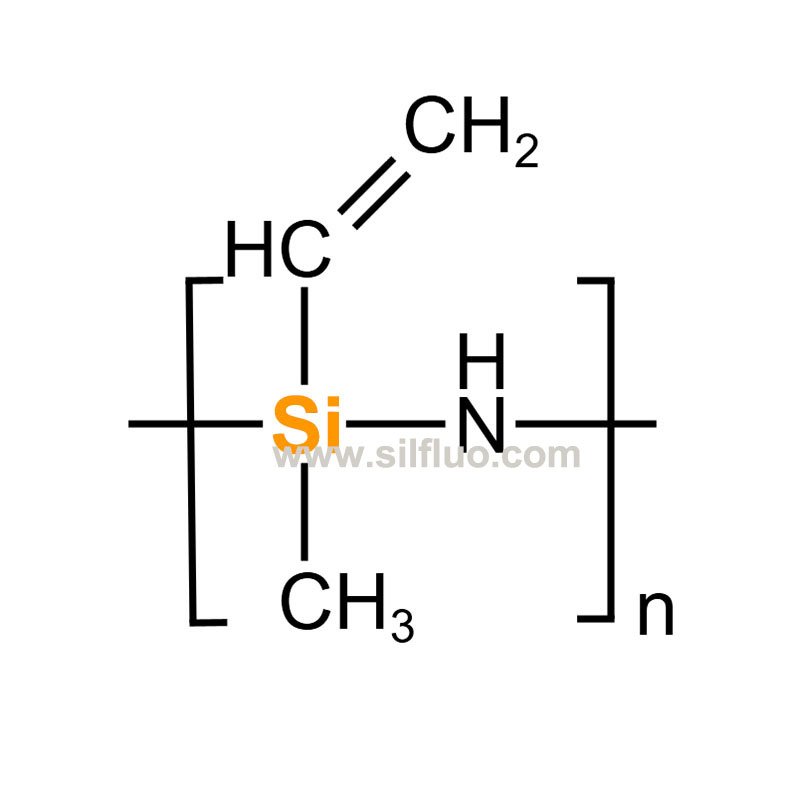

Applications of SILZ-351 Methylvinylsilazane

- The Si–N bonds readily react with hydroxyl-containing compounds, allowing methylvinylsilazane to function as an amine-type curing agent. It can also be used to modify hydroxyl-functional resins to enhance heat resistance and weather durability, including phenolic resins, epoxy resins, alkyd resins, and acrylic resins.

• Silazanes are widely applied in the rubber and ceramic industries. In silicone rubber processing, methylvinylsilazane serves as an effective processing additive, acting as a structural optimization and control agent while improving the heat resistance and mechanical strength of vulcanized rubber. Similarly, it is incorporated into other synthetic rubber systems to improve thermal stability and mechanical performance.

Technical Specifications

| Test Item | Specification | Test Method |

| Appearance | Light yellow to colorless transparent liquid | GB/T 1721-79 |

| Viscosity (Ford Cup No.4) | 11 s | GB/T 1723-1993 |

| Purity | ≥ 95% | Q/YX 10-2023 |

| Solid Content (120±2 °C) | > 96% | GB/T 1725-2007 |

| Density | 1.02 ± 0.01 g/mL | GB/T 6750-2007 |

| Molecular Weight | 255–591 | GB/T 27843-2011 |

| Pencil Hardness | ≥ 4H | GB/T 6739-2006 |

| Adhesion | Grade 0 | GB/T 9286-1998 |

| Salt Spray Resistance | > 500 h | GB/T 1771-2007 |

| Temperature | 165°C | 180°C | 200°C | 250°C | |

| Curing Conditions (DFT 5–25 μm, RH 50%) | Surface dry time | 1h | 0.2h | 0.1h | 0.1h |

| Full Cure Time | 1h | 1h | 0.5h | 0.5h | |

Standard Processing Procedure

Surface cleaning → Surface roughening → Cleaning and air drying → Methylvinylsilazane application → Curing

Instruction Manual

1. Surface roughening: Prior to coating, grind or sandblast the substrate surface to remove rust, dust, and contaminants. Surface preparation has a significant impact on coating performance. Recommended surface cleanliness is Sa 2.5, minimum St 3 without mill scale (GB/T 30790.4-2014).

2. Cleaning: Remove residual oil and dust using a dedicated cleaning agent or degreaser.

3. Substrate drying: Ensure the substrate surface is clean and completely dry before application.

4. Coating preparation: This product is a one-component system. Shake thoroughly before use and filter through a 400-mesh filter.

5. Application: Laboratory spray coating using a 0.5–1.0 mm nozzle spray gun is recommended for optimal appearance and uniformity.

6. Curing: After spraying, allow to tack-free dry for 10 minutes, then cure at 180 °C for 30 minutes (for coatings used below 400 °C), or cure at 250 °C for 30 minutes (for coatings used above 400 °C).

Storage & Handling

- Store in accordance with national regulations. The storage environment should be dry, cool, and well-ventilated, away from heat and ignition sources. Containers must be tightly sealed and handled with care.

2. Recommended storage temperature: 5–30 °C. Shelf life: 6 months.

3. Reseal containers tightly after opening if not fully used.

4. Prepared but unused materials must not be recycled and should be disposed of in accordance with local regulations.

5. Products beyond shelf life may only be used after passing quality inspection.

Packaging

In 1kg, 2kg, 5kg, 25kg pail.