The draft gear (buffer) is a critical component of rail transit vehicles. Its function is to mitigate longitudinal impulses and vibrations caused by changes in locomotive traction force or by collisions between vehicles during starting, braking, and shunting operations. It directly impacts key technical and economic indicators regarding railway transport efficiency, such as total traction weight, operating speed, total vehicle weight, and marshalling efficiency. As the performance of the draft gear directly influences operational safety and passenger comfort, countries worldwide attach great importance to the research and development of high-performance draft gears.

Currently, typical draft gears include grease-lubricated ring spring friction types and hydraulic types. However, they suffer from disadvantages such as poor low-temperature performance and aging resistance, short service life, complex manufacturing and maintenance processes, high cost, heavy self-weight, and high requirements for manufacturing precision. Consequently, it is difficult to promote them widely.

In China, passenger car draft gears are fundamentally based on grease-lubricated ring spring structures. These structures cannot meet the performance requirements of speed-up passenger cars, primarily manifested in the following aspects:

- Excessive initial pressure:The initial pressure can reach over 100kN.

- Excessive stiffness:In a 20-car passenger train, few draft gears actually perform a buffering function, and those that do utilize very little energy.

- Low absorption rate:Drop hammer tests demonstrate that the G1 draft gear has a low absorption rate, which easily causes continuous longitudinal impulses in the train.

- Short maintenance cycle:As the G1 draft gear uses grease lubrication, and the validity period of the grease is short, failure of the grease can lead to ring jamming, damage, or breakage, necessitating regular maintenance.

I. Introduction to Elastomeric Paste Buffer

The buffering medium used in the research of elastomeric paste buffers—elastomeric paste material—is a high-viscosity, compressible, and flowable unvulcanized organosilicone compound. It possesses high stability within the range of -80°C to +250°C, and is odorless, non-toxic, and non-polluting to the environment and personnel. Exhibiting both solid and liquid states, it is an ideal buffering medium for coupler draft gears.

Without the action of a return spring, the buffer utilizes the material’s high elasticity to achieve the restoration (return) stroke; utilizes its compressibility to achieve the compression stroke; and utilizes its good fluidity to achieve high capacity and low impedance capabilities. The flow viscosity of this material can be adjusted according to actual application needs, making its kinematic viscosity dozens or even hundreds of times greater than that of ordinary hydraulic oil. This simplifies the sealing difficulties typically associated with hydraulic buffers. If production process issues can be resolved, the cost of this material will not exceed $60/kg. Given that a buffer with a 15kJ capacity requires no more than 3kg of elastomeric paste, the material price meets the market requirements for the promotion of elastomeric paste buffers.

II. Basic Structural Principle of Elastomeric Paste Buffer

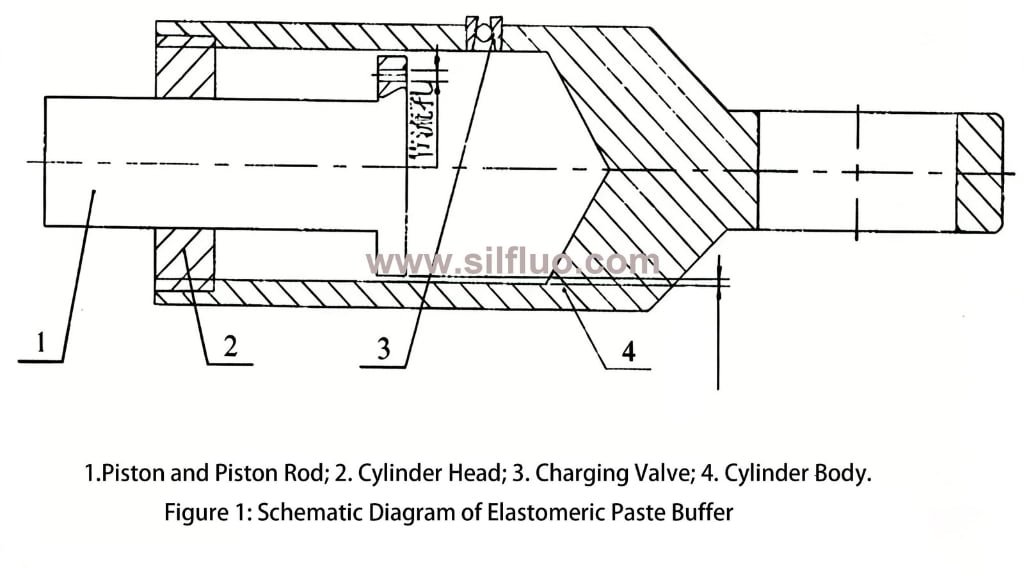

The elastomeric paste buffer mainly consists of a piston, piston rod, cylinder head, cylinder body, and charging valve (see Figure 1).

Working Principle: The elastomeric paste material is loaded into the buffer body and subjected to a specific pre-pressure. When the piston rod receives pressure, the elastomeric paste is compressed to generate resistive force (impedance). Impact energy is absorbed through the throttling action of the piston’s annular gap (or orifice) and the compressive deformation of the elastomeric paste material.

Due to the characteristics of the paste material, the greater the pre-pressure of the elastomeric paste and the movement speed of the piston, the greater the impedance. This is advantageous for increasing the buffer’s capacity under large impacts; specifically, the larger the impact, the greater the buffer’s capacity, and the smaller the impact, the smaller the capacity. When the external force on the piston rod is removed, the elastomeric paste expands volumetrically on its own, pushing the piston back to its original position. During this process, the elastomeric paste material flows back to its original position through the piston’s annular gap (or orifice) at a slower speed, realizing the buffer’s return action.

The connection between the buffer head and the coupler can be achieved via a flange connection or paired coupling rings. The tail end must be equipped with a rubber ball joint to accommodate the vertical height differences between couplers caused by track curvature.

III. Analysis of Standard Conditions for Elastomeric Paste Buffers

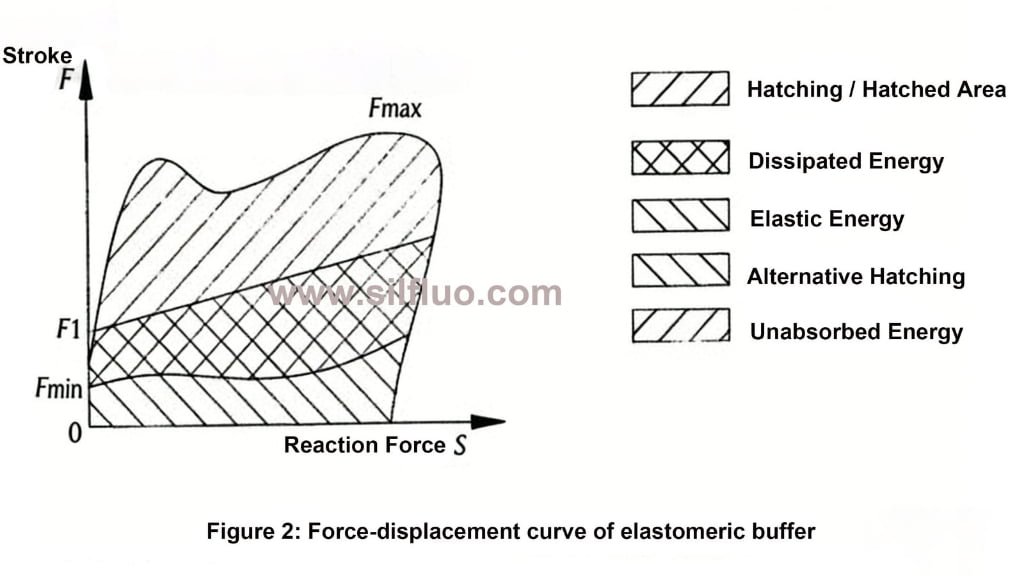

The technical parameters of the draft gear must be matched to the vehicle; vehicles with different technical configurations require distinct buffer specifications. The quality of a buffer is primarily determined by the compatibility of its performance with the vehicle and its ability to minimize longitudinal impact forces on the train to the greatest extent, thereby enhancing passenger comfort. The force-displacement curve of the elastomeric paste buffer is shown in Figure 2.

- Rated Capacity of Elastomeric Paste BufferRated capacity refers to the maximum impact or compressive kinetic energy that the buffer can accommodate within its rated stroke and impedance force range. This is a fundamental parameter of the buffer. For example, at a shunting speed of 5 km/h for the Shanghai Metro, the vehicle buffer capacity is 18.7 kJ.

- Rated Impedance Force of Elastomeric Paste BufferThe rated impedance force significantly impacts the vehicle’s longitudinal acceleration, the service life of vehicle components, and passenger comfort; generally, a lower value is preferred. However, due to design constraints—specifically to meet requirements for energy absorption and rapid return (reset)—the minimum impedance force should not be selected too low (e.g., the rated impedance force for Shanghai Metro vehicle buffers is 590 kN).

- Rated Stroke of Elastomeric Paste BufferThe rated stroke is one of the buffer’s critical parameters. Generally, a longer rated stroke is beneficial for increasing the rated capacity and reducing the rated impedance force. For instance, the stroke for Shanghai Metro vehicle buffers is 58 mm, while buffers for other urban rail systems have reached 73 mm. The magnitude of the stroke is often constrained by vehicle structural factors.

- Initial Pressure of Elastomeric Paste BufferInitial pressure (pre-load) is an important parameter of the buffer. According to relevant data, the magnitude of the initial pressure affects not only the train’s longitudinal acceleration but also the frequency of the vehicle’s longitudinal vibration. The higher the initial pressure, the greater the amplitude and frequency of the vehicle’s longitudinal vibration, and the poorer the passenger’s longitudinal comfort. Therefore, the lower the initial pressure, the better. However, limited by buffer manufacturing capabilities, it is generally set between 15 kN and 25 kN.

- Absorption Rate of the BufferThe absorption rate is the ratio of energy dissipated to energy accepted by the buffer during a single impact. The magnitude of the absorption rate indicates its ability to attenuate impact kinetic energy. The buffer’s absorption rate is defined as the ratio of the sum of damping energy dissipation and elastic energy to the total energy (see Figure 2). Generally, a higher rate is better; for urban rail vehicles, an absorption rate of approximately 80% is considered optimal.

- ConclusionCompared to conventional buffers, elastomeric paste buffers offer advantages such as high capacity, low impedance force, compact volume, light weight, and long maintenance intervals. Under the same capacity conditions, weight can be reduced by 30% to 50%, and the maintenance interval can reach up to 10 years (10a). With the development of urban rail transit and increasing requirements for passenger comfort, elastomeric paste buffers are poised for extremely widespread application.